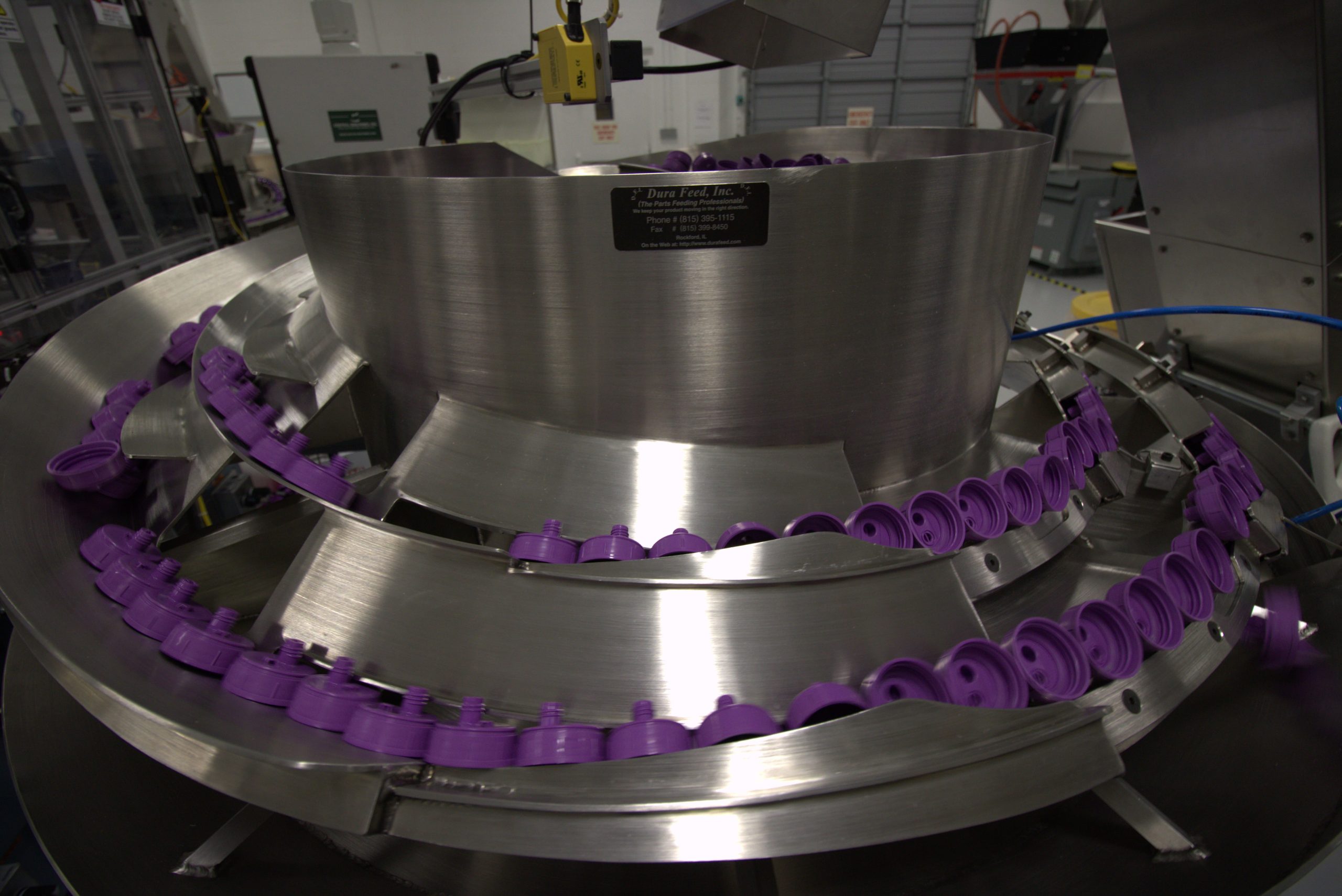

Quality

A comprehensive quality assurance program is implemented throughout the entire manufacturing cycle. In order to reach success in the quality process of our customers products, every employee at Plastek follows controlled procedures, work instructions, visual standards and quality plans to produce plastic injection molded parts that will meet or exceed the expectations of the customer.

See Our Policies & Certificates

Total Quality Management & Good Manufacturing Practices

The Plastek Group maintains a documented quality control management system designed and implemented to fulfill ISO 9001 requirements. This system creates a framework for clearly defining the control of materials, processes, and verification activities, thus providing our customers with confidence that the design and manufacture of The Plastek Group products are performed in a well-defined and controlled environment. The Good Manufacturing Practice (GMP) requirements specified in The Plastek Group manual are designed to:

- Establish guidelines consistent with The Plastek Group’s Quailty policy, which conform to applicable regulatory requirements for the manufacture and distribution of consumer product packages, medical devices, and other products.

- Aid employees to maintain the high quality standards of products manufactured and distributed by The Plastek Group.

- Instruct employees about good sanitation practices.

- Stress the importance of personal hygiene and cleanliness.

Quality Assurance

Plastek is committed to producing zero defects. The quality of any part depends on the quality of the material used. Every lot of resin delivered to Plastek is put through a comprehensive series of tests in our on site materials lab, before we accept it for production. This includes ASTM standard test methods such as melt flow, tensile and density tests.

Contact Us

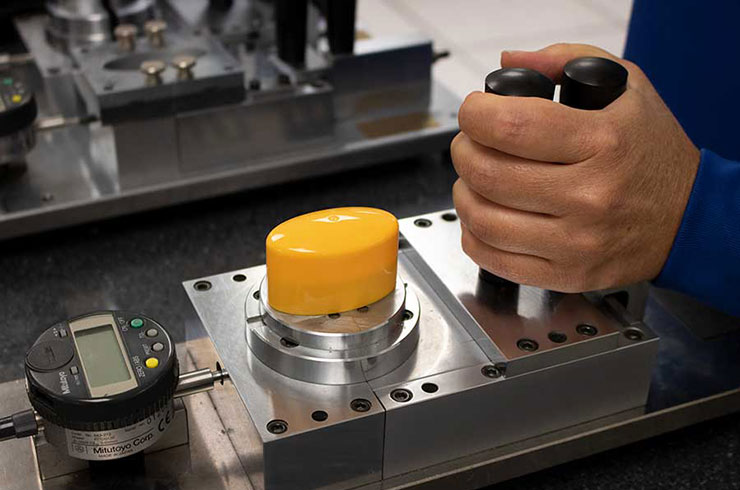

Metrology

We perform daily inspections on all parts that have been produced following industry standard tolerances.

- MicroVu, Automated Vision Measurement Systems.

- Coordinate Measurement Machines (CMM’s)

- Tool microscopes

- Customs Gaging

- Color Spectrophotometers

- Tensile testing

- Melt Flow and Volume testing

- Moisture Analizer

- Impact testing

- Density/Specific Gravity testing

- Shrink testing