Mold Design Services

Mold design is a Plastek specialty. Our in-house team implements the most advanced concepts and practices when creating custom products for your company’s needs. We tap into our diverse backgrounds and unparalleled expertise when creating molds that meet your specifications. We also utilize advanced software solutions to guide us through the process and enable us to make informed decisions:

- Mold Flow/Mold Cool

- AutoCAD Mechanical Desktop

- Simulia Abaqus

- Pro Engineer (3D Mold & Product Design)

- Expertise Mold Designers

We’ve created a comprehensive document database to coordinate, organize, and secure all relevant engineering data and make it easily accessible to our engineering staff.

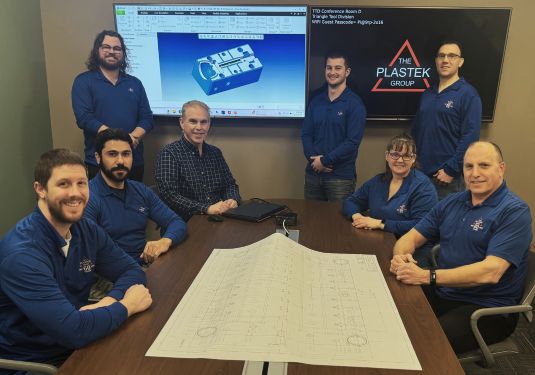

Our Engineering Team

Our experienced and knowledgeable cross-functional group of engineers cover multiple disciplines to ensure we provide the most comprehensive results. We implement a collaborative approach when partnering with our customers to develop innovative concepts that ensure a robust, reliable, and efficient supply chain.

Our engineers will bring these concepts to life by creating fully functional prototypes and production tooling processes. You can have confidence that the product we ultimately develop will provide the right solution for your business.

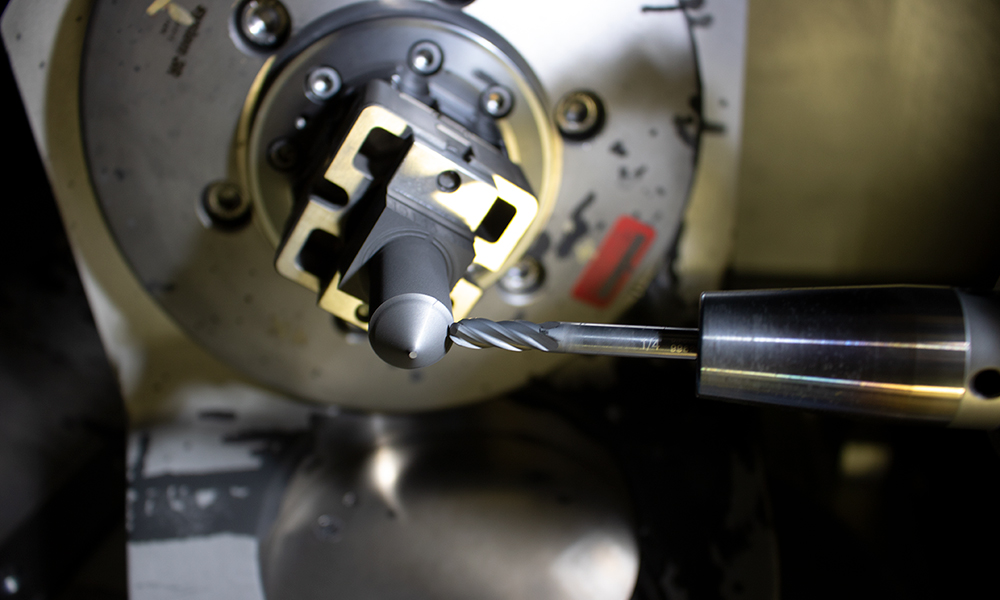

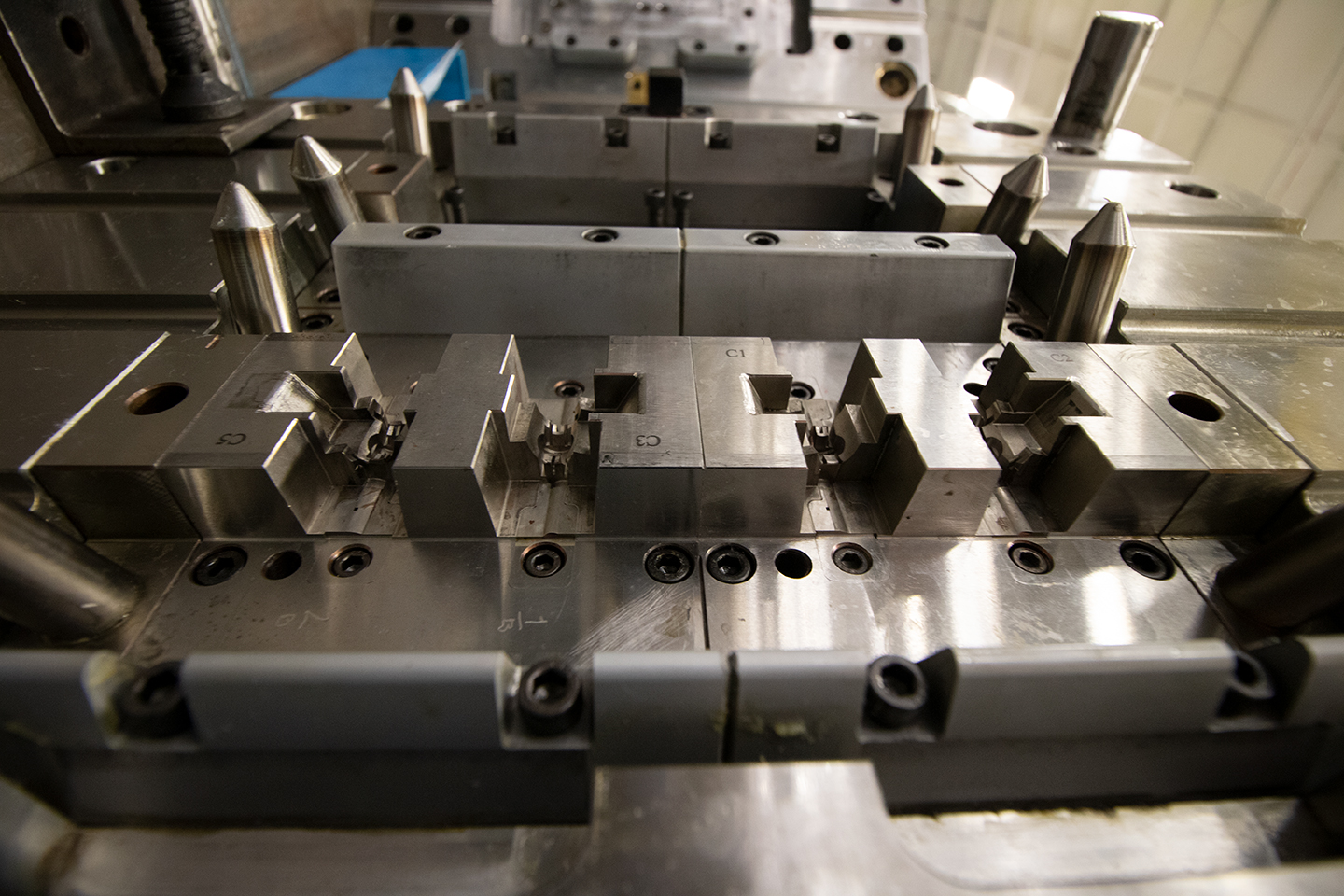

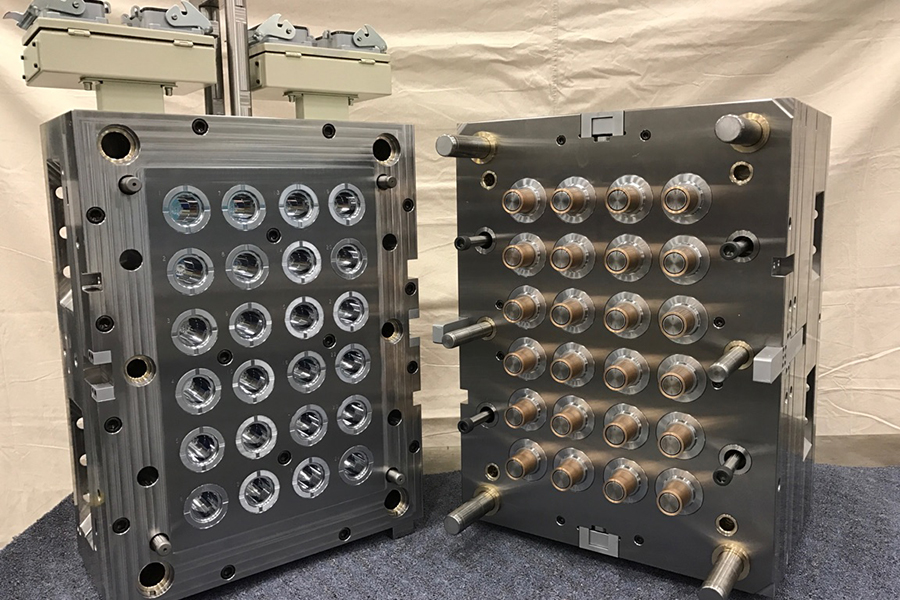

Request a QuoteFully Equipped Tool Shops

With four strategically located facilities, Plastek can execute high-quality contract plastic manufacturing projects for companies around the globe. Our fully equipped tool shops employ a large staff of toolmakers, engineers, and project managers, who share an unwavering commitment to delivering the best outcomes for every customer.

Our experience and expertise have enabled us to establish industry standards for designing and constructing molds in press maintenance and component interchangeability applications. We’ve also instituted toolmaking apprenticeships and other training initiatives to ensure our workers perform at a high level.

Examples of the advanced solutions we utilize in our tool shops include innovative CAD/CAM technologies that deliver superior results when designing parts and manufacturing molds. These systems also provide immediate updates to ensure we have the most accurate customer information on file.