Communication. The Plastek Group’s Best Practice

2019 Best Practices Book, Page 85-86

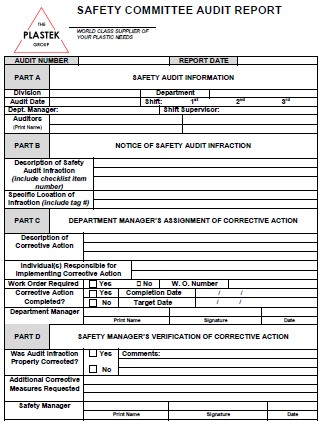

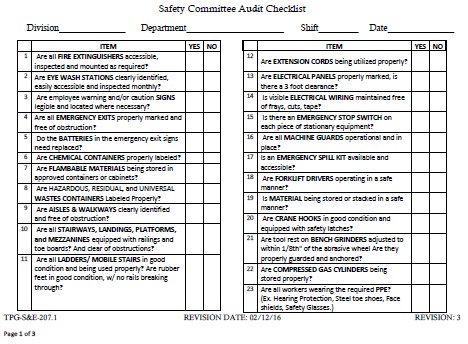

Every day each of us wakes up and starts on a path that will bring us to the end of the day. Some individuals have plans made well in advance, for that day, and maybe even weeks or months in advance. Some plan for the day that morning, and some, complete their day solely on the fly as the minutes and hours pass. You may fit your self into one or all these techniques, depending on the day, group you’re working with or task at hand. Whichever planning process describes you, it may or may not be considered your best practice when you think about starting your day. The Plastek Group, (Corporately headquartered in Erie, PA) can proudly say that their mornings, start with not just one (individual/group), but four. Global Supplier of all your plastic needs, present in the U.S., the U.K., Mexico and Brazil, an award-winning group specializing in injection molding, The Plastek Group can say that relying on best practices, is a best practice in itself. Plastek, founded in 1956, it can go without saying that many best practices have been trialed & errored, proven true, or used and recycled. With a large group of management, employees and customers, The Plastek Group, wakes up and starts its day with the potential opportunity for change every day. As change can be identified as having a great presence in daily operations, of The Plastek Group, what is a best practice developed to overcome and be prepared for change of events? You may think that adapting to change is the best practice here, but it’s not. What comes before being able to be adaptable? Communication. Declaring the objective or goal. Developing a plan. Identifying the team(s) of individuals/departments involved. Evaluating and benchmarking the project’s progress. Communication plays a large part in all stages of a project and has been declared as a (top) best practice at The Plastek Group. QC/Production/Customer ServiceMeetings: A neutral / common mindset for Plastek is to ensure that our teams are representing and being true advocates to the customer. Every morning department team leads gather to communicate specifications and progress of each running project, to ensure a satisfactory product, service and on time delivery. Monthly Employee Communication Meetings: SMD GM, Michael Liberatore has hosted these 30-minute meetings on all 3 shifts since 2013. KPIs, Safety, & Quality are three main topics covered with the floor employees every month. Liberatore says, “sharing this information with the employees is effective to the company’s bottom line, because it provides them with the opportunity to understand the expectations of the customers, the demands of Plastek, and encouragement to make better decisions in the role they play in production.” Shift/Stand Up Meetings: Brian Gardner, CPD GM emphasizes the importance of communicating with all floor employees on each shift at stand-up meetings. Gardner explains that this communication details where a project is left off and where it picks back up. Updates from shift to shift, day to day, minimizes the chance of continuing production with a part in non-conformance or defect, which therefore limits scrap/rework requirements. Internal Audits: Plastek continues communication across every department within each of its manufacturing facilities, in a form of internal audits. Some of these audits include: Monthly Safety Audits & Safety Committee Meetings, annually progressive Operations Audits (auditing to every clause of the BRC standards), Continuous Training & Improvement Audits, and Social Compliance Audits (CDP, EcoVadis, SEDEX SMETA). Performing Internal Audits assists in an operating system of checks & balances. Communicating the results of such audits, in the form of bulletin postings or group meetings, can allow for the recognition of benchmark achievements and delegation of assignment for improvement(s) as needed. Office Renovations: Providing an office layout, such as adjacent placement of like offices, creates a conducive work environment for the communication and collaboration of departmental teams, such as customer service, scheduling, production, and quality control. The Plastek Group strives to build mutual beneficial relationships between its employees and customers. With a world of distance, cultures, and business minds integrated into the global (Plastek) group that exists today, communication happens in many different forms. It is a best practice. A tool to share expression, vision, and positive drive for a specific outcome. A valuable resource that when working as a team, cannot be gone without. The Plastek Group is a community that wakes up, to show up ready to work together, overcoming yesterday’s benchmark and setting a new. Knowing their first plan of communication is to practice, their best practice.